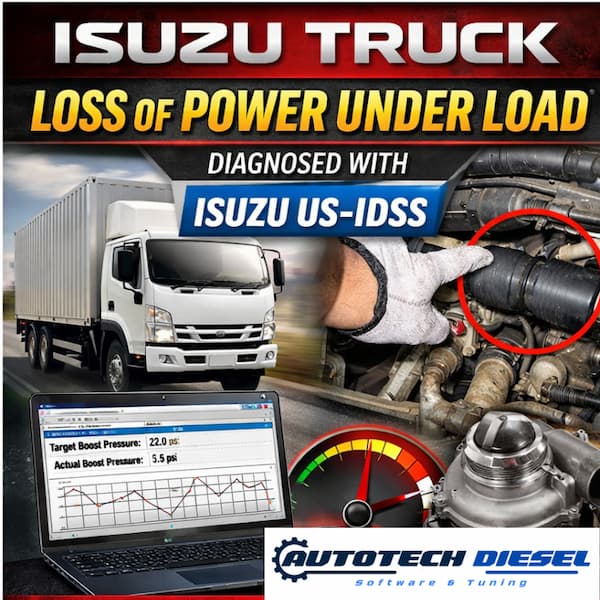

Isuzu Truck Loss of Power Under Load – Real Diagnostic Case Using Isuzu US-IDSS

Loss of power under load is one of the most common complaints on Isuzu diesel trucks, especially when the vehicle is carrying heavy cargo or driving uphill. In this real workshop case, Autotech Diesel used Isuzu US-IDSS to accurately diagnose the problem, identify the root cause, and restore full engine performance.

This article shares the real diagnostic process, including symptoms, live data analysis, and the final repair solution — exactly how professional technicians handle it in the workshop.

🚛 Vehicle Symptoms (Customer Complaint)

The customer reported the following issues:

-

Truck feels weak when driving with load

-

Poor acceleration, especially from low RPM

-

Engine runs normally at idle

-

No obvious black smoke from exhaust

-

Fuel consumption increased slightly

The vehicle could still be driven, but performance was clearly reduced under real working conditions.

🔍 Step 1: Initial Diagnosis with Isuzu US-IDSS

We connected the truck to Isuzu US-IDSS using a compatible diagnostic interface and performed a full system scan.

Results:

-

No critical engine DTCs stored

-

No limp mode active

-

Engine ECU communication normal

Because no hard fault codes were present, live data analysis was required.

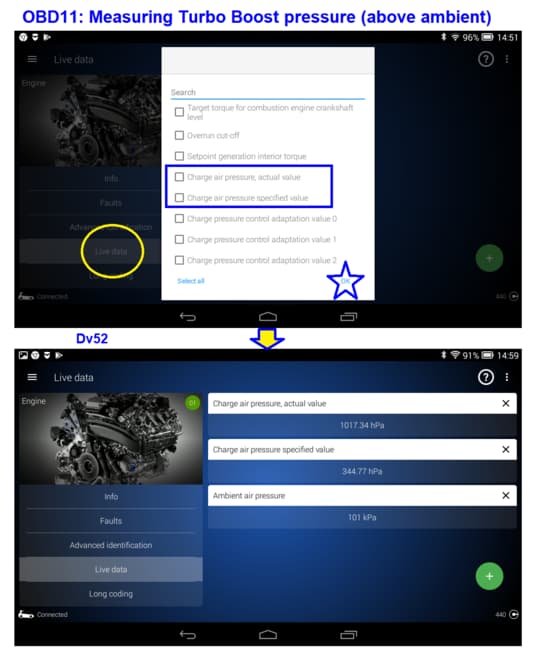

📊 Step 2: Live Data Monitoring (Key Step)

Using US-IDSS Live Data, we monitored the following parameters during a road test with load:

-

Target Boost Pressure

-

Actual Boost Pressure

-

Mass Air Flow (MAF)

-

Engine Load Percentage

-

Accelerator Pedal Position

⚠️ Abnormal Finding:

-

Actual Boost Pressure was significantly lower than Target Boost

-

Difference increased under load

-

ECU was requesting boost, but turbo system could not deliver it

This confirmed a turbo / air system-related issue, not a fuel problem.

🛠️ Step 3: Physical Inspection Based on Diagnostic Data

Guided by the US-IDSS data, we inspected the intake and boost system:

-

Turbocharger hoses

-

Intercooler pipes

-

Boost pressure sensor (MAP)

-

Clamps and rubber connectors

Root Cause Found:

✅ Cracked turbo boost hose between turbocharger and intercooler

-

Crack only opened under pressure

-

Not visible during static inspection

-

Caused boost pressure leak only when engine was under load

This type of failure is very common and often missed without live data diagnostics.

🔧 Step 4: Repair & Verification

Repair Performed:

-

Replaced damaged turbo hose

-

Checked all boost system connections

-

Cleaned boost pressure sensor

Final Test:

-

Cleared adaptive values

-

Road test with full load

-

Re-checked Live Data

✅ Result:

-

Target Boost ≈ Actual Boost

-

Full engine power restored

-

Smooth acceleration

-

No fault codes returned

🎯 Why Isuzu US-IDSS Was Essential in This Case

Without Isuzu US-IDSS, this problem could easily be misdiagnosed as:

❌ Injector issue

❌ Fuel pump problem

❌ ECU fault

US-IDSS allowed us to:

-

Compare commanded vs actual values

-

Diagnose without unnecessary part replacement

-

Save time and cost for the customer

This is exactly why dealer-level diagnostic software is critical for modern diesel trucks.

🧰 Software Used in This Case

-

Isuzu US-IDSS Diagnostic Software

-

Functions used:

-

Full system scan

-

Live data monitoring

-

Road test diagnostics

-

ECU data comparison

-

👉 Available with remote installation and support at Autotech-Diesel.com

⭐ Need Help Diagnosing Isuzu Truck Problems?

At Autotech Diesel, we specialize in:

-

Isuzu US-IDSS diagnostic software

-

Remote diagnostic support

-

Real workshop solutions for diesel trucks

If your Isuzu truck has:

-

Loss of power

-

Turbo issues

-

Fuel system faults

-

No fault codes but poor performance

📞 Contact Autotech-Diesel.com

Our technicians can help you diagnose and solve the problem quickly and professionally, wherever you are.